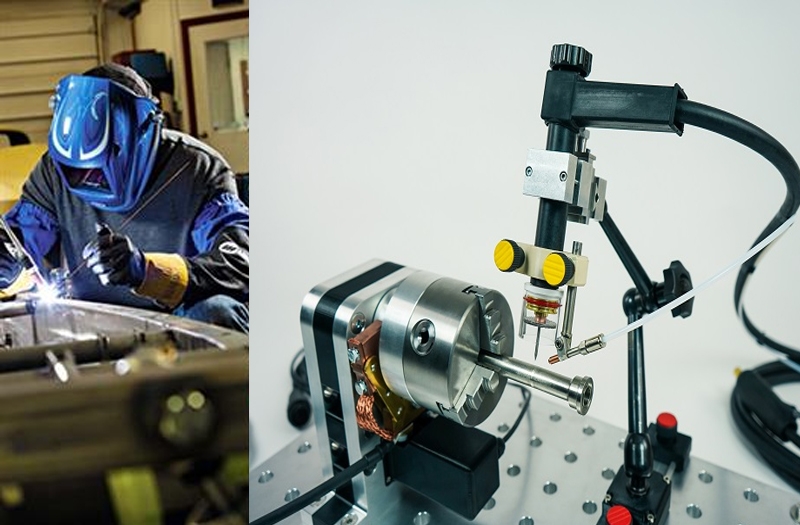

One of the most important - and simplest - ways to create strong welds is to maintain your welding equipment properly. Maintaining your welder machine is simple to undertake and can wind up saving you a lot of time and money in the long run in terms of machine life as well as welding performance and quality. You can avoid certain typical welding failures and avoid having to pay for expensive repairs on neglected or inadequately kept equipment by performing routine machine maintenance work.

depending on the type of welding equipment you are using, maintenance requirements will vary. the following article we will go to share about the welding machine maintenance work for your reference.

PROPERLY WELDING MACHINE MAINTENANCE WORK

Modern technology, such as electric welding machines, are employed frequently in human labor. But as a result of the prolonged labor process, many welding machine parts will be vulnerable to mistakes in operation and will be highly challenging to fix. In order to extend the useful life and performance of electric welding equipment and prevent unintentional mishaps brought on by machine failure while in use, it is necessary to learn the best ways to maintain them.

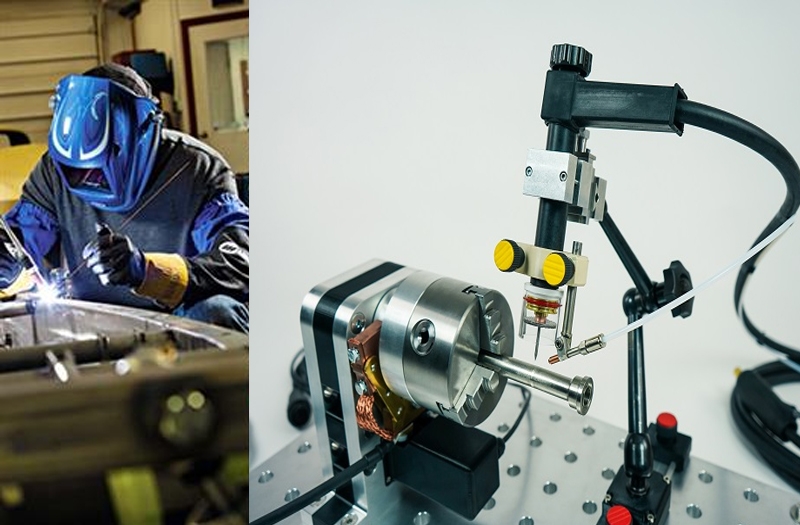

here are some important steps in maintaining the best electric welder:

- Before beginning work, we must first inspect every component of the machine to determine whether it is still in good operating order. Make sure the equipment is dust-free and grounded. If any machine component is found to be malfunctioning, it must be fixed quickly to prevent harm to other components. machine.

- after that, before running the equipment, we must comprehend how it operates. Observe the manufacturer's instructions and be familiar with the installation process. To prevent fire and explosion when using electric arc welding machines, the ground should be set up carefully. Use accessories appropriate for the machine type as well.

- make sure the workplace is safe, sanitary, and well-ventilated. Control the equipment situation strictly to avoid outside influences.

- When in use, it's important to set the proper working hours, and the manufacturer's recommendations for electrodes and fillers must be followed. The machine's condition will worsen, possibly even resulting in an explosion, if the setting is incorrect or the manufacturer's instructions are not followed.

- store the device in a dry and safe place after use. equipment can be damaged if dropped or bumped, and corroded if exposed to high humidity environments, dust accumulation in electrical circuits or important parts can cause the machine to fail quickly or reduce performance. job.

at the same time, we should also choose quality electric welding machines from reputable stores in the domestic market, to avoid buying the wrong product with low quality, high price,... if we apply the best maintenance methods for electric welding machines, we will certainly prolong the life of our equipment and increase labor productivity in the process of working.

performing the above maintenance work stages on a regular basis will definitely help the welding machine always achieve high efficiency in operation and have a long life. do not forget to refer to the good quality welding machines at swisstech to distributing genuine products at affordable prices.

depending on the type of welding equipment you are using, maintenance requirements will vary. the following article we will go to share about the welding machine maintenance work for your reference.

PROPERLY WELDING MACHINE MAINTENANCE WORK

Modern technology, such as electric welding machines, are employed frequently in human labor. But as a result of the prolonged labor process, many welding machine parts will be vulnerable to mistakes in operation and will be highly challenging to fix. In order to extend the useful life and performance of electric welding equipment and prevent unintentional mishaps brought on by machine failure while in use, it is necessary to learn the best ways to maintain them.

here are some important steps in maintaining the best electric welder:

- Before beginning work, we must first inspect every component of the machine to determine whether it is still in good operating order. Make sure the equipment is dust-free and grounded. If any machine component is found to be malfunctioning, it must be fixed quickly to prevent harm to other components. machine.

- after that, before running the equipment, we must comprehend how it operates. Observe the manufacturer's instructions and be familiar with the installation process. To prevent fire and explosion when using electric arc welding machines, the ground should be set up carefully. Use accessories appropriate for the machine type as well.

- make sure the workplace is safe, sanitary, and well-ventilated. Control the equipment situation strictly to avoid outside influences.

- When in use, it's important to set the proper working hours, and the manufacturer's recommendations for electrodes and fillers must be followed. The machine's condition will worsen, possibly even resulting in an explosion, if the setting is incorrect or the manufacturer's instructions are not followed.

- store the device in a dry and safe place after use. equipment can be damaged if dropped or bumped, and corroded if exposed to high humidity environments, dust accumulation in electrical circuits or important parts can cause the machine to fail quickly or reduce performance. job.

at the same time, we should also choose quality electric welding machines from reputable stores in the domestic market, to avoid buying the wrong product with low quality, high price,... if we apply the best maintenance methods for electric welding machines, we will certainly prolong the life of our equipment and increase labor productivity in the process of working.

performing the above maintenance work stages on a regular basis will definitely help the welding machine always achieve high efficiency in operation and have a long life. do not forget to refer to the good quality welding machines at swisstech to distributing genuine products at affordable prices.