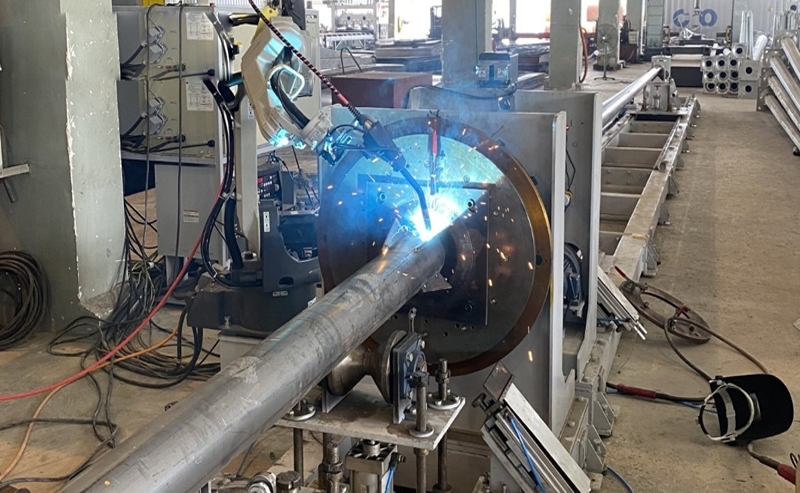

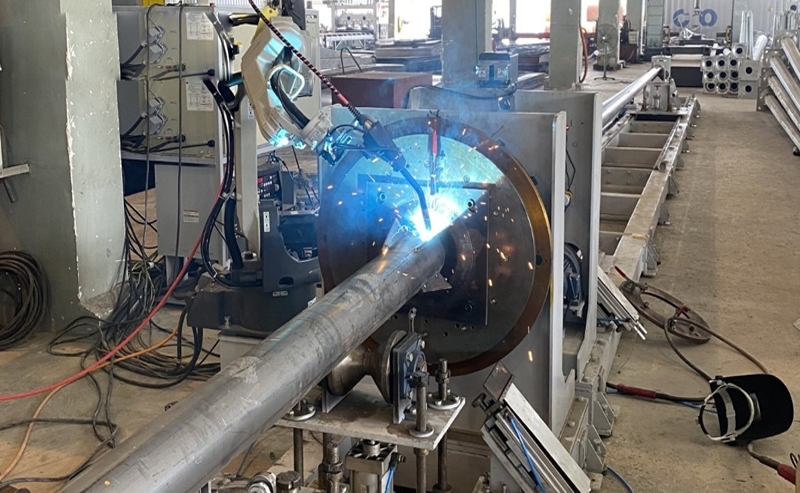

orbital pipe automatic welding machine is a new type of automatic welding equipment that combines new generation control technology and welding process technology. it is mainly used for filling and welding. cap long distance pipelines such as oil, natural gas, heat, water supply, etc.

ABOUT THE AUTOMATIC STEEL PIPE ORBITAL WELDING MACHINE

automatic orbital welding machine adopts narrow and thin groove structure, occupies a small space and does not damage the layer. heat insulation and anti-corrosion coating on the outside of the pipeline.it integrates many advanced intelligent welding technologies, adopts custom imported brand digital welding power supply, and has mig, with pulse functions and dual pulse, the whole system is optimized for integration.

it adopts high quality alloy steel shell of impact resistant engineering, exclusive patented appearance design, exquisite and generous, compact and portable and highly integrated. steel grades above x65-x120 and pipe diameters over 6” can be used for pipes with excellent adaptability to thermal environments high and low.

light welding head, integrated wire feeding system, installation is completed in seconds, convenient and fast.

the self-developed narrow and thin end rail can be applied to heat pipes without damaging the insulation. the track is made of high quality spring steel belt, which has high strength and adaptability. good response. the installation is simple and reliable, and the joints of the rails are well connected and oversized.

multi-function remote control, chinese/english interface, hand-held remote control can do solder bead selection, left and right height adjustment, swing width and so on. of the torch, in accordance with ergonomics.

RULES OF WORK

the single torch external welding machine is mainly composed of welding head, welding wire feeding system, remote control, welding power source, cable, path, etc., through a walking head on the road to weld all positions. position. a single torch can weld different welds, which is a highly efficient external pipe welding equipment. during the welding process, the welder is required to participate in the welding process to some degree. it is protected by carbon dioxide or mixed gas (80% argon + 20% carbon dioxide), and the solder wire can be solid or cored soldered.

SCOPE OF APPLICATION

applicable working conditions: on-site welding and prefabrication of various long-distance pipelines (oil, natural gas, etc.), heat pipes, water supply pipes, etc.

applicable environment: indoor workshop, field

welding material: carbon steel, stainless steel, alloy steel, low temperature steel, etc.

welding angle: flat welding, vertical welding, horizontal welding, overhead welding, all 5g . welding positions

applicable welds: pipes with diameter above φ168mm and wall thickness greater than 5mm can be used.

for thick-walled pipes, straight pendulum and angular pendulum functions can be selected, and multi-layer and multi-pass welding methods are also adopted.

types of welding: pipe circumferential welding of inner and outer pipes, pipe elbows, pipe flanges, transverse and longitudinal welding of tanks, horizontal welding of pipe piles, flange welds, longitudinal seams of pipes straight, etc.

PERFORMANCE ADVANTAGE

welding parameter presets and real-time adjustment and precise control help to create smooth transition of welding parameters and improve welding stability and welding quality.

straight pendulum and angle pendulum can be switched freely, can do multiple welding modes in one machine, suitable for welding pipes with different wall thicknesses, and effectively improve the welding quality ratio .

thin and narrow steel groove design, flexible, heat pipes can be assembled and applied without destroying the insulation, strong rigidity, light, convenient for transportation, welding head holder and higher gear stroke accuracy.

combined with intelligent fusion expert program wisefusion to optimize arc ignition when welding, for smooth arc start and high success rate

small and portable, high degree of integration, exclusive patented design, exquisite and generous.

high degree of intelligence, less dependent on labor, ensuring the consistency and reliability of welding parameters.

exquisite welding shape, welding quality can meet defect detection requirements.

integrated welding head, compact structure, stable wire feed, high arc stability, light.

using advanced digital micro-control technology, combined with excellent motor control system makes the control more precise and stable.

anti-interference communication technology is adopted between the welding parts, which has the characteristics of strong anti-interference ability and real-time dynamic response, which is convenient for use in harsh working environment, and can be used used for automatic welding operations in complex construction environments.

system ip23s protection level, adapt to ambient temperature: -40 70.

handheld lcd remote control, intuitive touch screen: used to set, display, modify and store welding parameters, support data upload. chinese/english interface, conveniently observe and adjust welding parameters at any time, easy to operate, friendly and intuitive.

head with integrated wire pulling system to ensure stable and reliable wire feeding.

the tip fits into a narrower space and can be better used for the construction of the station's process pipeline.

gear tracking design, stronger welding accuracy and longer life.

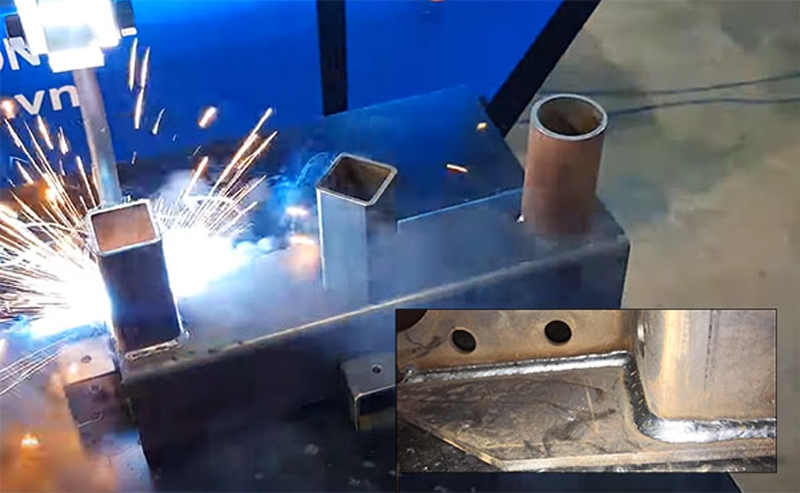

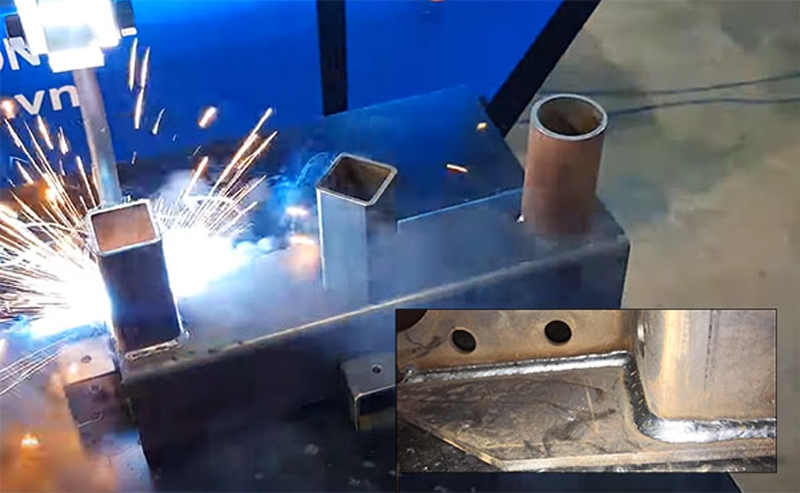

WELDING EFFECT

orbital welding machine efficiency: fast speed, high production efficiency, and can be increased by about 3-4 times compared to manual arc welding.

welding seam quality: the weld seam has a nice appearance, no pitting, slag, confusion, etc. and good welding quality. second level ray test pass rate is more than 98% and test pass rate ultrasonic testing is close to 100%.meet the requirements for testing pressure or impact, tensile, bending and other mechanical properties.

ABOUT THE AUTOMATIC STEEL PIPE ORBITAL WELDING MACHINE

automatic orbital welding machine adopts narrow and thin groove structure, occupies a small space and does not damage the layer. heat insulation and anti-corrosion coating on the outside of the pipeline.it integrates many advanced intelligent welding technologies, adopts custom imported brand digital welding power supply, and has mig, with pulse functions and dual pulse, the whole system is optimized for integration.

it adopts high quality alloy steel shell of impact resistant engineering, exclusive patented appearance design, exquisite and generous, compact and portable and highly integrated. steel grades above x65-x120 and pipe diameters over 6” can be used for pipes with excellent adaptability to thermal environments high and low.

light welding head, integrated wire feeding system, installation is completed in seconds, convenient and fast.

the self-developed narrow and thin end rail can be applied to heat pipes without damaging the insulation. the track is made of high quality spring steel belt, which has high strength and adaptability. good response. the installation is simple and reliable, and the joints of the rails are well connected and oversized.

multi-function remote control, chinese/english interface, hand-held remote control can do solder bead selection, left and right height adjustment, swing width and so on. of the torch, in accordance with ergonomics.

RULES OF WORK

the single torch external welding machine is mainly composed of welding head, welding wire feeding system, remote control, welding power source, cable, path, etc., through a walking head on the road to weld all positions. position. a single torch can weld different welds, which is a highly efficient external pipe welding equipment. during the welding process, the welder is required to participate in the welding process to some degree. it is protected by carbon dioxide or mixed gas (80% argon + 20% carbon dioxide), and the solder wire can be solid or cored soldered.

SCOPE OF APPLICATION

applicable working conditions: on-site welding and prefabrication of various long-distance pipelines (oil, natural gas, etc.), heat pipes, water supply pipes, etc.

applicable environment: indoor workshop, field

welding material: carbon steel, stainless steel, alloy steel, low temperature steel, etc.

welding angle: flat welding, vertical welding, horizontal welding, overhead welding, all 5g . welding positions

applicable welds: pipes with diameter above φ168mm and wall thickness greater than 5mm can be used.

for thick-walled pipes, straight pendulum and angular pendulum functions can be selected, and multi-layer and multi-pass welding methods are also adopted.

types of welding: pipe circumferential welding of inner and outer pipes, pipe elbows, pipe flanges, transverse and longitudinal welding of tanks, horizontal welding of pipe piles, flange welds, longitudinal seams of pipes straight, etc.

PERFORMANCE ADVANTAGE

welding parameter presets and real-time adjustment and precise control help to create smooth transition of welding parameters and improve welding stability and welding quality.

straight pendulum and angle pendulum can be switched freely, can do multiple welding modes in one machine, suitable for welding pipes with different wall thicknesses, and effectively improve the welding quality ratio .

thin and narrow steel groove design, flexible, heat pipes can be assembled and applied without destroying the insulation, strong rigidity, light, convenient for transportation, welding head holder and higher gear stroke accuracy.

combined with intelligent fusion expert program wisefusion to optimize arc ignition when welding, for smooth arc start and high success rate

small and portable, high degree of integration, exclusive patented design, exquisite and generous.

high degree of intelligence, less dependent on labor, ensuring the consistency and reliability of welding parameters.

exquisite welding shape, welding quality can meet defect detection requirements.

integrated welding head, compact structure, stable wire feed, high arc stability, light.

using advanced digital micro-control technology, combined with excellent motor control system makes the control more precise and stable.

anti-interference communication technology is adopted between the welding parts, which has the characteristics of strong anti-interference ability and real-time dynamic response, which is convenient for use in harsh working environment, and can be used used for automatic welding operations in complex construction environments.

system ip23s protection level, adapt to ambient temperature: -40 70.

handheld lcd remote control, intuitive touch screen: used to set, display, modify and store welding parameters, support data upload. chinese/english interface, conveniently observe and adjust welding parameters at any time, easy to operate, friendly and intuitive.

head with integrated wire pulling system to ensure stable and reliable wire feeding.

the tip fits into a narrower space and can be better used for the construction of the station's process pipeline.

gear tracking design, stronger welding accuracy and longer life.

WELDING EFFECT

orbital welding machine efficiency: fast speed, high production efficiency, and can be increased by about 3-4 times compared to manual arc welding.

welding seam quality: the weld seam has a nice appearance, no pitting, slag, confusion, etc. and good welding quality. second level ray test pass rate is more than 98% and test pass rate ultrasonic testing is close to 100%.meet the requirements for testing pressure or impact, tensile, bending and other mechanical properties.